If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp : +8613395319660

Whatsapp : +8613395319660

![]() Email : [email protected]

Email : [email protected]

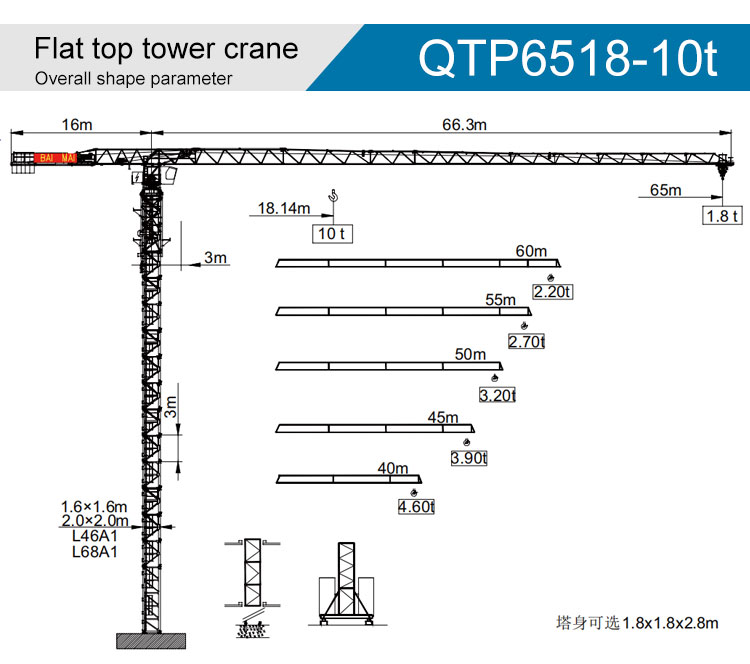

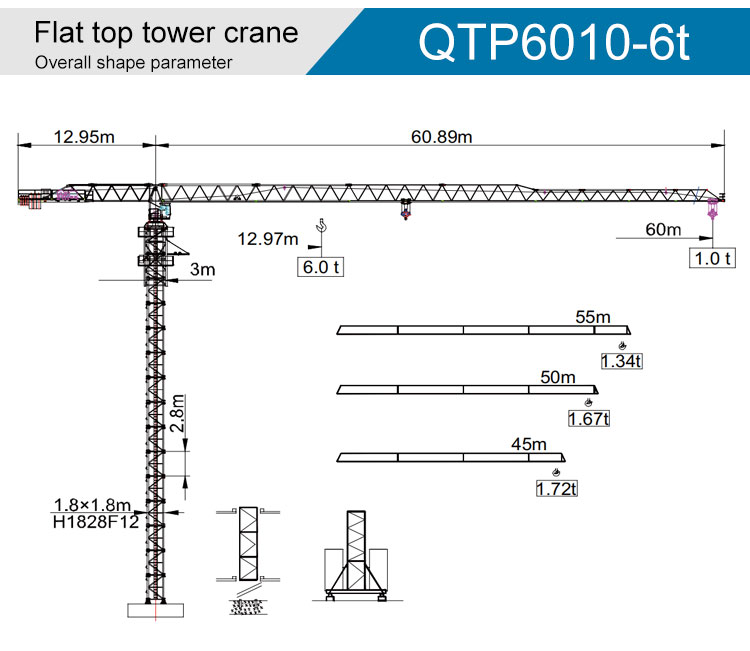

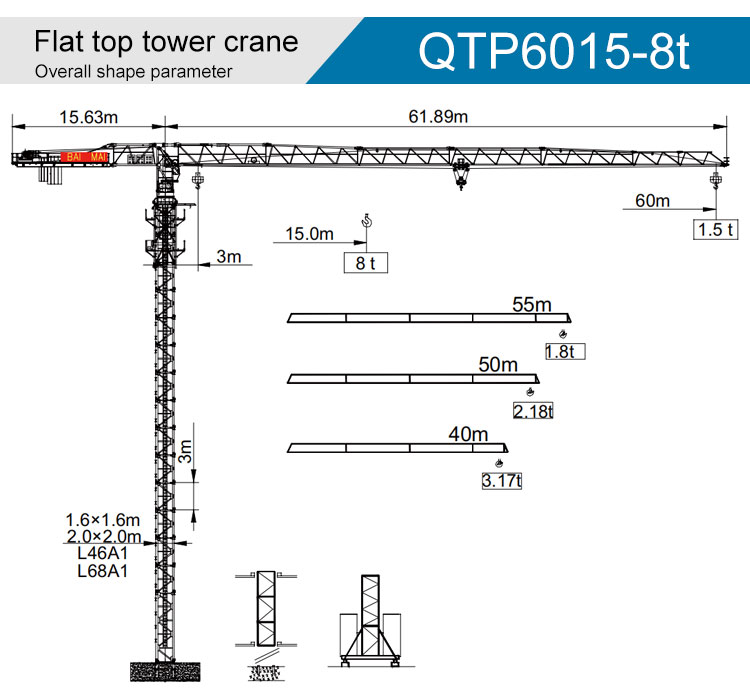

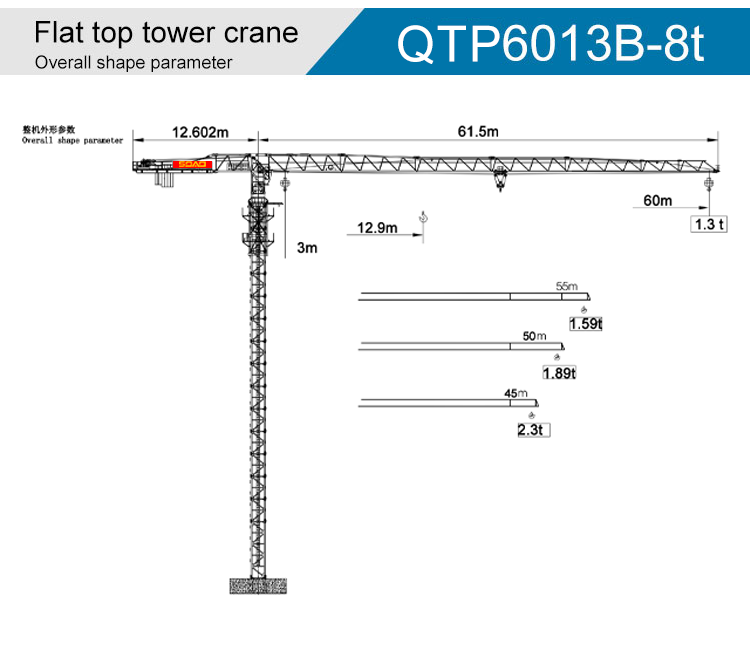

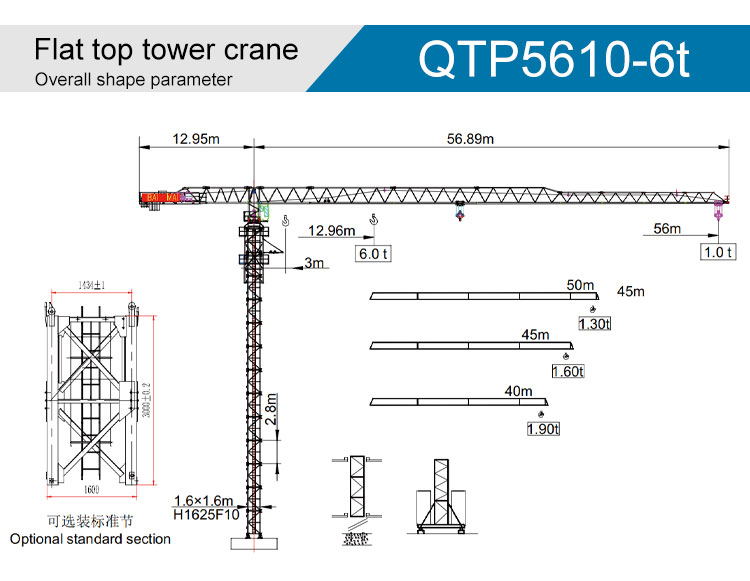

Here we list 5 best-selling Flat-Top Tower Crane models along with their specifications for your reference. We also manufacture over 10 models of flat-top tower cranes, and we can customize special parameters. Additionally, we supply both new and second-hand tower cranes to meet diverse applications. Tower crane accessories and standard mast sections are available for separate purchase. Please feel free to contact us for tower crane prices and customization services.

Without the tower top structure of traditional tower cranes, its boom is directly connected to the slewing platform, making the top of the crane flat. This structure enables the crane to have better spatial adaptability when working in a group of towers or passing through obstacles, effectively avoiding collisions with other cranes or protruding parts of buildings.

The boom is generally connected by plug-in or pin-type, which is easy to install and disassemble. This connection method enhances the stability of the boom and reduces the safety hazards caused by loose connections.

Many flat-top cranes adopt modular design concepts, and the connection between components is simpler and standardized, which is convenient for transportation and on-site assembly, especially for projects that require frequent transfer of work sites.

It has a large lifting height and lifting weight, which can meet the lifting needs of heavy objects in engineering projects such as high-rise buildings and large bridges. Its lifting mechanism is usually equipped with high-performance motors and reducers, and the lifting speed can be adjusted according to actual operation requirements, with high work efficiency.

The slewing bearing device adopts advanced technology, which enables the crane to achieve 360° flexible rotation. The rotation speed is stable and can be precisely controlled, which is convenient for adjusting the hoisting position in a small space.

The crane arm is long, and through the pitch operation of the crane arm and the amplitude change of the trolley, it can cover a large working radius range and can effectively serve a large area of construction sites.

Equipped with a variety of safety protection devices such as lifting weight limiter, lifting torque limiter, height limiter, amplitude limiter, and slewing limiter. These devices can monitor the working status of the crane in real time. When there are dangerous situations such as overload and overlimit, they will automatically sound an alarm and stop the corresponding dangerous actions to ensure the safety of the operation.

The design takes into account the stability under various working conditions. Through reasonable counterweight setting, structural optimization of the crane arm, and reinforcement of the chassis, it is ensured that the crane will not tip over when lifting heavy objects. Even in complex working environments and adverse weather conditions, it can maintain good stability.

Please send your requirements below, and we will get back to you soon. Thank you!