If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp : +8613395319660

Whatsapp : +8613395319660

![]() Email : [email protected]

Email : [email protected]

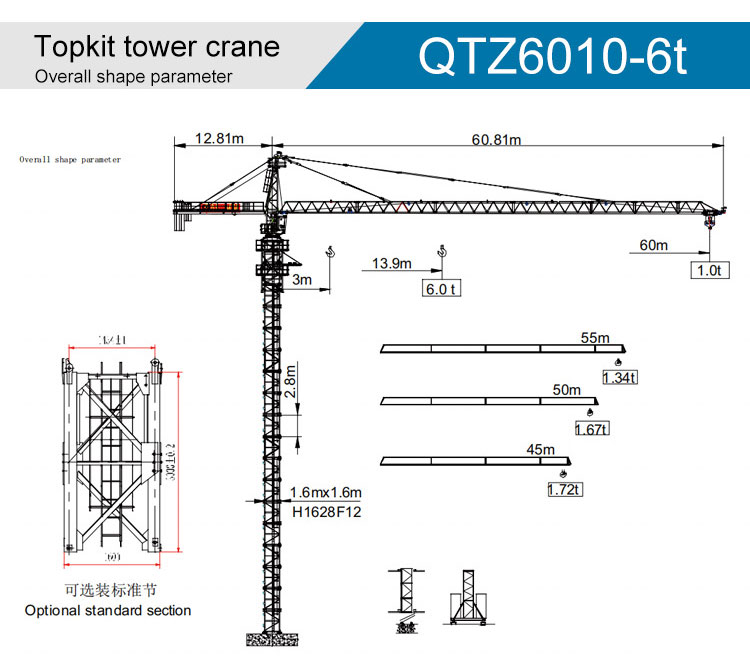

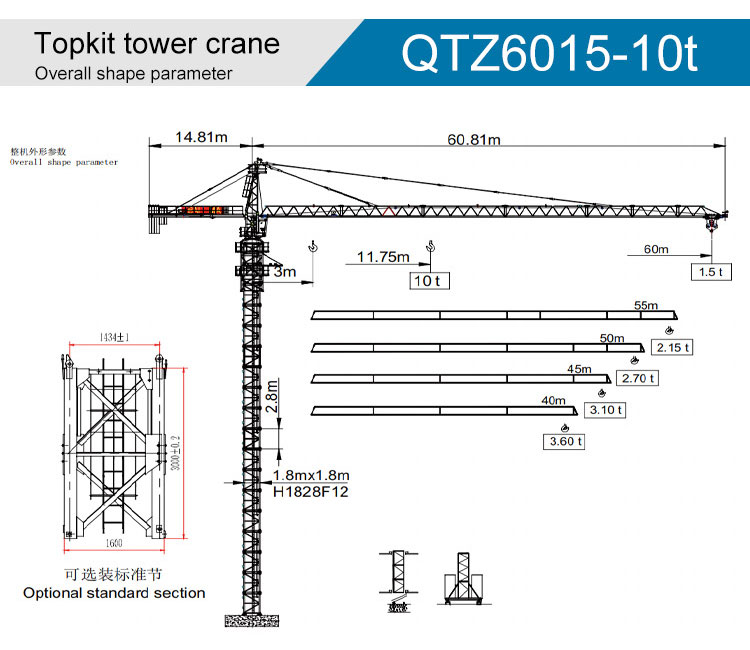

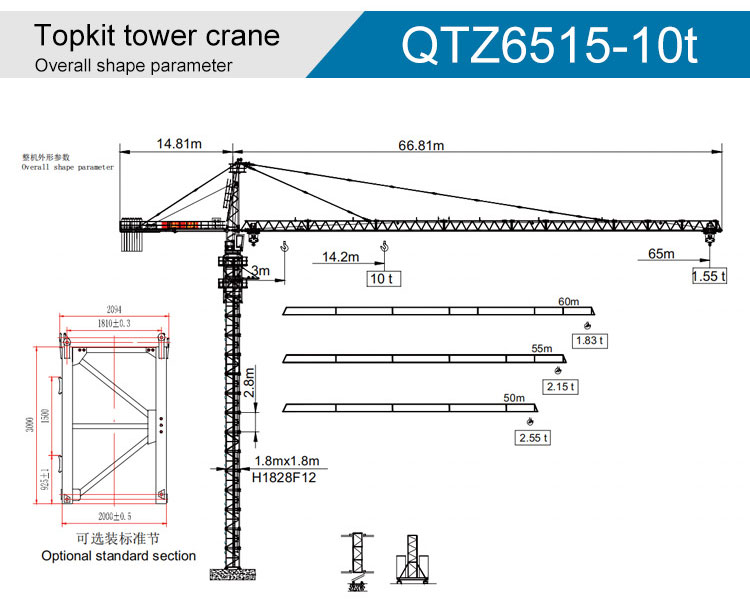

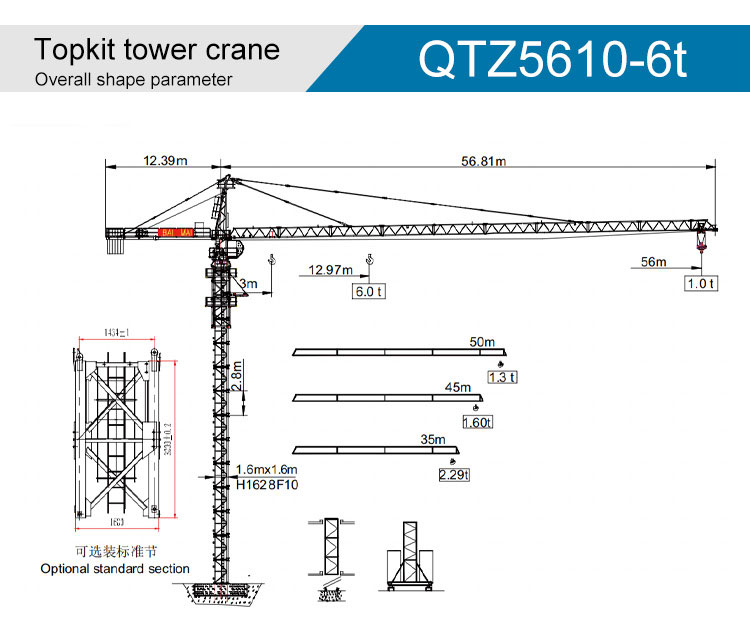

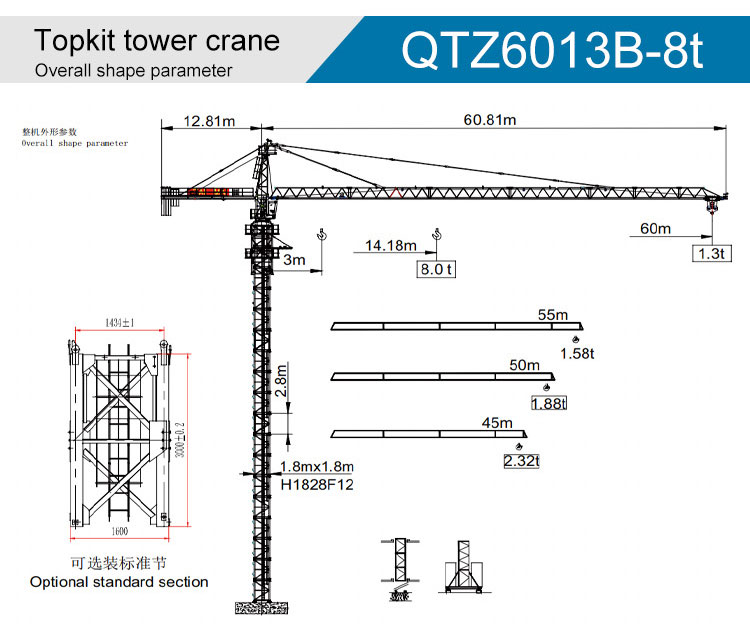

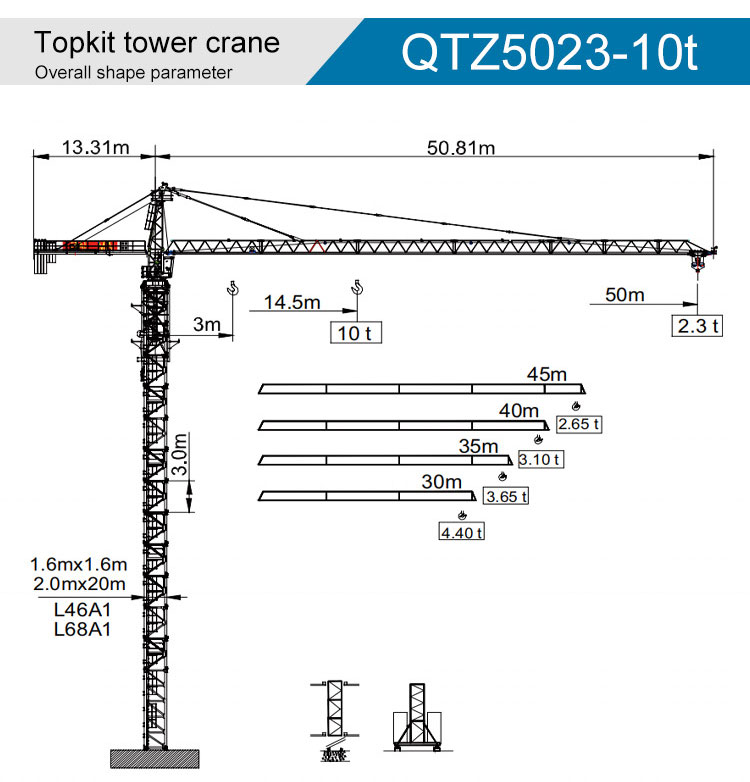

We list 6 best-selling models of hammerhead tower cranes along with their specifications for your reference. We also offer over 10 additional models to meet diverse construction needs, with the option to customize special parameters. Furthermore, we supply both new and second-hand tower crane products for different construction sites. Accessories and standard sections are available for individual purchase. Our tower cranes are exported to more than 40 countries and regions worldwide and have received widespread acclaim. Feel free to contact us for tower crane prices and customized product services.

1. Structural design

1. Structural designThe horizontal boom design is adopted, and the boom is kept in a horizontal state. The radius of the load is changed by moving the load trolley installed on the boom, so as to realize the hoisting operation at different positions. This design makes the force condition of the boom relatively simple and the structural requirements are relatively low.

Compared with some other complex tower crane types, the structure of the hammerhead crane is relatively simple, without too many complex boom luffing mechanisms, etc., and the number of parts is relatively small.

Performance

It can provide a large lifting torque, which can meet the hoisting needs of heavier objects in various types of construction, and is suitable for hoisting large building components, mechanical equipment, etc.

The luffing mechanism, slewing mechanism, etc. usually adopt advanced variable frequency stepless speed regulation scheme, with high working speed and good speed regulation performance. It can flexibly adjust the speed according to the actual operation needs, while improving work efficiency and ensuring the stability of the operation.

Wide operating range: Through the movement of the load trolley on the horizontal boom and the slewing movement of the crane itself, a large operating area can be covered. At the same time, some hammerhead tower cranes also have a variety of working methods, such as outrigger fixation, chassis fixation, embedded bolt fixation, external wall attachment, etc., which can adapt to different construction sites and building structure requirements.

The driver’s cab is independently external, with a wide field of vision and large internal space, which creates a good working environment for the operator, making it convenient for the driver to observe the hoisting operation and more convenient and accurate operation.

Due to the relatively simple structure and the use of mature and reliable electrical control systems and mechanical components, the failure rate of hammerhead cranes is low, and daily maintenance and maintenance work is relatively easy, reducing maintenance costs and downtime.

Safety guarantee

Equipped with various mechanical or mechatronic safety devices, such as lifting weight limiter, torque limiter, height limiter, amplitude limiter, slew limiter, etc., it can monitor various parameters in real time during the operation of the crane, and issue an alarm and stop the operation in time when an abnormal situation occurs, ensuring the safety of the crane and the operator.

The electrical control system adopts PLC control, which improves the reliability and safety of the system. At the same time, it adopts electrical components produced by professional electrical factories with advanced foreign technology, which have long service life and few failures, further ensuring the stable operation of the crane.

Please send your requirements below, and we will get back to you soon. Thank you!